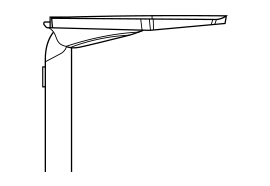

Raise & lower columns have become the standard solution for areas with restricted access. ALC’s Echalon® Raise & Lower system achieves quick, controlled, safe operation without compromise.

Our Echalon® Raise & Lower system has been unique to the market since its Mk I debut in 2009.

With an improved appearance and an enhanced locking system, our current Mk III model is our most capable system to date.

Our Range:

- ≤6m Echalon® Raise & Lower – ‘Standard Hinged’ (Conical or Stepped Column Options)

- 6.1-8m Echalon® Raise & Lower – ‘Standard Hinged’ (Stepped Column Only)

- 8.1-10m Echalon® Raise & Lower – ‘High Hinged’ (Stepped Column Only)

- 10.1-12m Echalon® Raise & Lower – ‘High Hinged’ (Two-part Stepped Column Only)

Passive Safe Options Available for Echalon® columns ≤8m Height (AGL).

*Please Note: ‘Standard Hinged’ products are lowered by the operator stood at ground level. ‘High Hinged’ columns require the use of an Aerial Work Platform (AWP) to access hinge point at approx. 4m (AGL).

| Standard 145mm - 76mm 5m Echalon | | | | | |

| 4.1kN | 9kN | 13kN | 20kN | 25kN |

| Default Direction | MA-04161 | MA-00155 | MA-00039 | MA-00145 | MA-01367 |

| Towards | MA-05055 | MA-01551 | MA-00043 | MA-01196 | **Contact ALC Technical Team** |

| Away | MA-05056 | MA-00261 | MA-00042 | MA-00414 | **Contact ALC Technical Team** |

| Left | MA-03671 | MA-00703 | MA-00040 | MA-05057 | **Contact ALC Technical Team** |

| Right | MA-03681 | MA-01136 | MA-00041 | MA-05058 | **Contact ALC Technical Team** |

| Min/Max Loading | 0.1kg - 1.2kg | 1.3kg - 8.3kg | 8.4kg - 15.8kg | 15.9kg - 21.1kg | **Contact ALC for specific calculations** |

| Standard 145mm - 76mm 6m Echalon | | | | | |

| 4.1kN | 9kN | 13kN | 20kN | 25kN |

| Default Direction | Not Suitable | MA-00717 | MA-00055 | MA-00268 | MA-00996 |

| Towards | Not Suitable | MA-03508 | MA-00059 | MA-01634 | **Contact ALC Technical Team** |

| Away | Not Suitable | MA-02304 | MA-00058 | MA-00554 | **Contact ALC Technical Team** |

| Left | Not Suitable | MA-02602 | MA-00056 | MA-00759 | **Contact ALC Technical Team** |

| Right | Not Suitable | MA-02603 | MA-00057 | MA-01526 | **Contact ALC Technical Team** |

| Min/Max Loading | Not Suitable | 0.1kg - 4.1kg | 4.2kg - 10.2kg | 10.3kg - 14.1kg | **Contact ALC for specific calculations** |

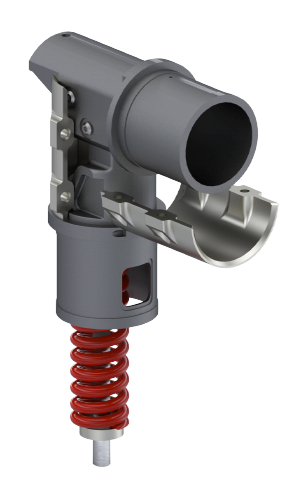

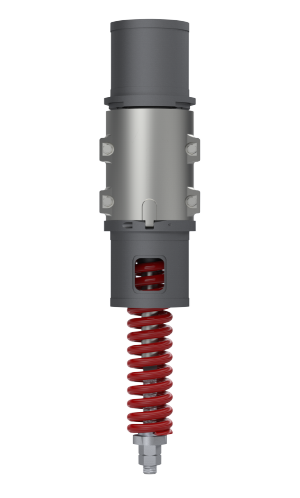

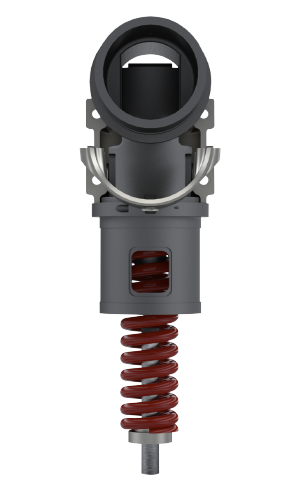

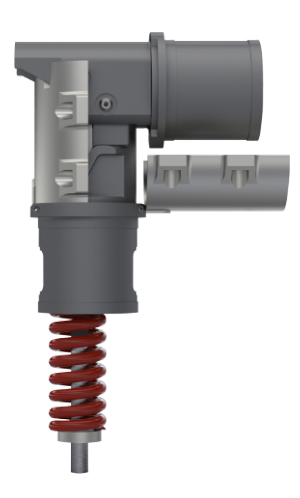

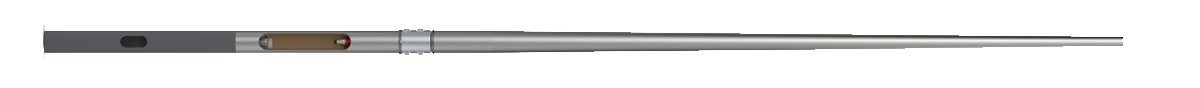

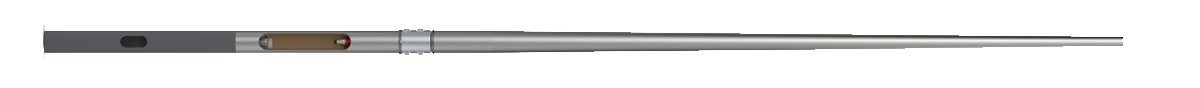

ALC casts aside cumbersome winching equipment, opting for a self-contained spring-assisted ‘cartridge’ system requiring just a hand-sized key to operate.

The Echalon® Raise & Lower system can be operated in even the most remote and confined of locations, allowing for ease of maintenance with minimal road closures or possession orders.

The spring-assisted cartridge can be fine-tuned through the door section, matching the relevant applied load. Once this is complete, the column will raise and lower smoothly with minimal effort.

With a locking mechanism to secure the lowered column in place, operators can safely conduct their work.

ALC’s ability to install the cartridge at any orientation (360°) allows our clients to specify the exact angle at which the column will fall, ensuring ‘safe working areas’ are respected and objects in the vicinity of the column are avoided during maintenance.

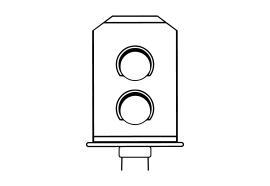

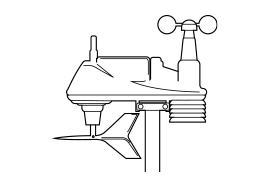

From lighting to CCTV, the Echalon® Raise & Lower system is the pragmatic solution.

Find the full Operational Video covering the construction of the system & its safe operation on our Youtube Channel.

01639 852 502

01639 852 502